|

Product Menu Trucking Utility Accessories Boat/Box Trailer Residential Shop Fitting Marine Collectable's Price List Dynaplas Pty. Ltd. 45 Wellington Street RIVERSTONE NSW 2765 SYDNEY AUSTRALIA Ph: +61 2 9627 5944 sales@dynaplas.com.au Dynaplas Pty. Ltd. 26 Corbould Rd COOLUM BEACH 4573 QUEENSLAND AUSTRALIA Ph: +61 7 5324 1557 sales@dynaplas.com.au  Facebook Facebook

|

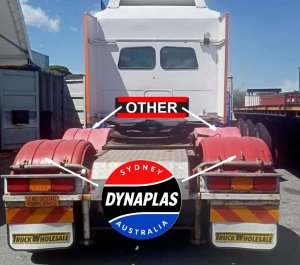

1. What are Dynaplas truck mudguards made from?

Dynaplas truck mudguards are made from high-quality polyethylene, a tough and flexible material designed to handle Australia's harsh road and weather conditions. Unlike metal mudguards, they won't rust, dent, or crack, making them a long-lasting and reliable choice for trucks, trailers, and heavy vehicles. 2. Why choose polyethylene mudguards over steel or fiberglass? Polyethylene mudguards are lightweight, impact-resistant, and corrosion-free, making them stronger and more durable than steel or fiberglass. They're flexible under stress, meaning they won't shatter or bend permanently. This makes them the preferred option for truck operators looking for reliability, low maintenance, and long service life. 3. Do Dynaplas mudguards comply with Australian road regulations? Yes, Dynaplas truck mudguards are designed and manufactured to meet or exceed Australian transport regulations. This ensures your vehicle remains road legal while benefiting from the durability and performance of polyethylene mudguards. Fleet operators, truck owners, and trailer manufacturers across Australia rely on Dynaplas for compliance and safety. 4. What truck sizes do Dynaplas mudguards suit? Dynaplas supplies mudguards for a wide range of vehicles, including single wheel, dual wheel, and super single truck and trailer configurations. Whether you operate a small truck, semi-trailer, or an entire transport fleet, Dynaplas offers mudguard solutions to suit different wheel sizes and vehicle requirements. 5. Are Dynaplas mudguards resistant to UV damage and cracking? Yes, all Dynaplas mudguards are UV-stabilised, meaning they won't fade, crack, or become brittle in the hot Australian sun. Their impact-resistant polyethylene construction ensures they can withstand years of use in the toughest road and weather conditions without losing strength or appearance. 6. Can I buy Dynaplas truck mudguards individually or in bulk? Dynaplas mudguards are available for both individual purchase and bulk orders. Whether you need a single replacement mudguard or a complete set for your fleet, Dynaplas can supply the right quantity to meet your needs. Bulk orders are ideal for transport companies and trailer manufacturers. 7. Are Dynaplas mudguards easy to install? Yes, Dynaplas mudguards are designed for quick and easy installation. They are lightweight, making them easier to handle than steel alternatives. With standard brackets and mounting kits available, you can fit them securely to your truck or trailer with minimal tools and downtime. 8. Do you supply mudguard brackets and fitting kits? Yes, Dynaplas supplies a complete range of accessories including mudguard brackets, stays, and fitting kits. This ensures a secure installation and compatibility with different truck and trailer setups. Buying mudguards with the correct mounting kits guarantees a professional fit and longer service life. 9. Can Dynaplas mudguards be customised? Yes, Dynaplas mudguards can be supplied in a range of sizes, styles, and colours to suit specific trucks or fleet branding. For larger orders, customisation options are available to match your company's requirements. This makes Dynaplas mudguards a popular choice for transport operators wanting a professional and consistent fleet look. 10. Where are Dynaplas mudguards made? Dynaplas mudguards are proudly manufactured in Australia at our Riverstone, NSW facility. With over 40 years of expertise in polyethylene manufacturing, Dynaplas has become a trusted supplier to the trucking and transport industry, offering Australian-made products designed for strength, durability, and compliance. 11. Do Dynaplas mudguards come with a warranty? Yes, all Dynaplas truck mudguards come with a quality guarantee against manufacturing defects. Our long-lasting polyethylene material ensures a durable product, but if a rare issue occurs, our warranty provides peace of mind for truck owners and fleet operators alike. 12. How do I clean and maintain Dynaplas mudguards? Dynaplas mudguards are very low maintenance and easy to clean. Simply wash them with water and mild detergent to remove dirt, mud, and road grime. Unlike steel, they don't require painting, polishing, or rust prevention, saving time and maintenance costs for operators. 13. Do you ship Australia-wide and internationally? Yes, Dynaplas supplies mudguards across Australia and can also export internationally. Whether you're located in Sydney, Melbourne, Brisbane, Perth, or overseas, we provide reliable shipping options to get our products to your workshop, depot, or fleet on time. 14. How long do Dynaplas mudguards last compared to steel ones? Dynaplas polyethylene mudguards typically last much longer than steel alternatives because they don't rust, corrode, or dent. Steel mudguards can deteriorate quickly in wet or coastal environments, while Dynaplas mudguards are built to withstand harsh road conditions, reducing replacement costs over time. 15. Who uses Dynaplas mudguards? Dynaplas mudguards are trusted by truck owners, fleet operators, trailer manufacturers, and transport companies across Australia and internationally. They are the mudguard of choice for heavy-duty applications where durability, compliance, and long service life are essential.

|

A terrific group of professional and friendly people to work with

A terrific group of professional and friendly people to work with The team here is absolutely wonderful! I had an exceptional experience from start to finish with professionalism from the whole team and couldn’t be happier with the service. Highly recommend if you are looking for reliable and professional support.

The team here is absolutely wonderful! I had an exceptional experience from start to finish with professionalism from the whole team and couldn’t be happier with the service. Highly recommend if you are looking for reliable and professional support. I have been using dynaplas mudguards and couldn't be happier with them. They're lightweight, easy to install, and do a fantastic job keeping mud and water off the vehicle. One thing I really appreciate is that the color doesn’t fade over time, even after lots of sun exposure—they still look like new. They're also tough enough to handle bumps and everyday wear without cracking. Overall, a great product that offers excellent protection and durability. Highly recommended

I have been using dynaplas mudguards and couldn't be happier with them. They're lightweight, easy to install, and do a fantastic job keeping mud and water off the vehicle. One thing I really appreciate is that the color doesn’t fade over time, even after lots of sun exposure—they still look like new. They're also tough enough to handle bumps and everyday wear without cracking. Overall, a great product that offers excellent protection and durability. Highly recommended The team at Dynaplas is great! Excellent product range, quality, and service all wrapped up with a totally professional, customer-focused team. From enquiry to delivery, nothing was too much trouble. Highly recommended.

The team at Dynaplas is great! Excellent product range, quality, and service all wrapped up with a totally professional, customer-focused team. From enquiry to delivery, nothing was too much trouble. Highly recommended. Their team is awesome. Exceptional experience for me. Recommend for anyone! 10/10

Their team is awesome. Exceptional experience for me. Recommend for anyone! 10/10 Excellent customer service throughout the purchase process, my order was filled, shipped safely(no damage in transit)and arrived in Perth within 7 days, delivery was via Big Post and their service was great also, thanks Jen and the team at Dynaplas

Excellent customer service throughout the purchase process, my order was filled, shipped safely(no damage in transit)and arrived in Perth within 7 days, delivery was via Big Post and their service was great also, thanks Jen and the team at Dynaplas